Small spot energy dispersive X-ray fluorescence (ED-XRF) spectrometer optimized for precious metal testing

OVERVIEW

- The market recognized gold standard for element analysis of precious metals

- Wide scope of > 30 elements backed by extensive factory calibrations providing the best accuracy for traces and majors

- Up to a factor of 3 shorter measurement times: choose exceptional results at conventional measurement times, or conventional results at exceptional measurement times

Accuracy of elemental analysis is often critical — especially in assessing precious metals. For other applications speed is even more important: High-volume hallmarking centers demand both fast and accurate analysis. In addition, all users prefer analyzers that are robust, convenient, and easy to operate, with helpful software and easy transfer of results into a lab network. In dealing with precious metals, of course, users also prize nondestructive sampling.

For years, SPECTRO MIDEX has turned in ultra-reliable top-rated XRF performance in all these areas. It’s the industry standard in many assay laboratories worldwide. Now a fifth generation of SPECTRO MIDEX analyzers — with up to triple the sensitivity even of previous models — approaches fire assay technology in precision, while greatly surpassing it in speed and ease. And it’s fully optimized for precious metals applications.

The compact new SPECTRO MIDEX incorporates the latest developments in ED-XRF detector technology, using high count rate and high resolution. These smart new innovations help make it one of the most advanced midrange laboratory XRF benchtop analyzers available for precious metals testing. So users can choose significantly increased precision — even for minor and trace element content — or substantially faster testing for higher sample throughput.

BROCHURES

SPECTRO MIDEX Precious Metals (PDF, en)

Read MoreWHITEPAPERS

Analyzing Precious Metals (PDF, en)

Precious metals require — and reward — careful analysis. But analysts face various difficulties. The scope of precious metals analysis extends from trace levels to 100%. Most of these metals are resistant to dissolution by all but the strongest acids. Some traditional analytical methods like fire assay are time-consuming and demand a high level of skill.

Three modern techniques offer widely used solutions. Energy-dispersive X-ray fluorescence (ED-XRF) and optical emission spectrometry (OES) can be used without specialist analytical training to rapidly and accurately analyze bullion, jewelry, and alloys. A variation of OES, inductively coupled plasma optical emission spectrometry (ICP-OES), is an ideal tool for the analysis of bulk materials such as ores, and for the determination of trace impurities.

Several instruments available from SPECTRO Analytical Instruments represent the state of the art in these techniques. This paper describes their application to precious metals analysis.

APPLICATIONS

Application Reports

Application Brief: Precious metals testing with ED-XRF spectrometry (XRF-101-AB)

Precious metals demand careful analysis. This paper examines the use of the SPECTRO MIDEX with regards to precious metals testing. With considerable improvement on already high levels of precision and speed, it provided excellent analytical results.

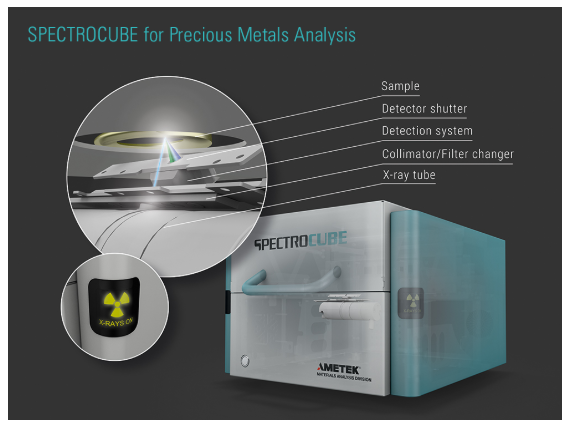

The SPECTROCUBE ED-XRF analyzer delivers easy, reliable, accurate, high-throughput analysis for a variety of applications

OVERVIEW

- Fastest in its class: Twice as fast as typical testing, high precision with high speed

- Excels in scope and accuracy: Optimized application packages

- Unparalleled ease-of-use: Just three simple steps to accurate results

The new SPECTROCUBE ED-XRF analyzer delivers easy, reliable, accurate, high-throughput analysis for a variety of applications, e.g. analysis of precious metals, compliance screening or analysis of fuels and lube oils.

The SPECTROCUBE analyzer incorporates state-of-the-art ED-XRF technology, including high-resolution and high-count rate detector to deliver short measurement intervals, effortless workflow via intuitive software, and low downtime. SPECTROCUBE enables a fast, smooth workflow even for minimally trained users for an unparalleled ease of use. Its compact footprint fits tight benchtop spaces yet accommodates a wide range of tiny to large samples. For most analyses, SPECTROCUBE delivers the required accuracy with only one general-purpose calibration.

PRECIOUS METALS ANALYSIS

The new SPECTROCUBE ED-XRF analyzer for precious metals testing delivers easy, reliable, accurate, high-throughput analysis for testing centers, hallmarking and assay offices, and jewelry makers — at twice the speed of other analyzers in its class.

The new SPECTROCUBE ED-XRF analyzer for precious metals testing delivers easy, reliable, accurate, high-throughput analysis for testing centers, hallmarking and assay offices, and jewelry makers — at twice the speed of other analyzers in its class.

The SPECTROCUBE analyzer incorporates state-of-the-art nondestructive ED-XRF detector technology, including high-resolution and high-count rate, to deliver short measurement intervals, effortless workflow via intuitive software, and low downtime.

SPECTROCUBE enables a fast, smooth workflow even for minimally trained users for an unparalleled ease of use. The sample analysis is performed in three quick and easy steps, with the intuitive software presenting the relevant information on a single screen. Its compact footprint fits tight benchtop spaces yet accommodates a wide range of tiny to large samples. For most analyses, SPECTROCUBE delivers the required accuracy with only one general-purpose calibration.

Featuring exceptional speed and performance, SPECTROCUBE provides high precision for a wide range of concentration levels — plus testing times as low as 15 seconds that enable a throughput of up to hundreds of samples per working day. On jewelry samples large or small, the instrument can analyze an area down to a spot size of 0.2 mm that’s among the industry’s smallest spot sizes.

Unlike many other XRF analyzers, SPECTROCUBE features the latest in high-resolution silicon drift detector (SDD) technology and an ultra-high count rate to register minor and trace amounts of some nonprecious components. Moreover, if required, SPECTROCUBE can deliver up to three-times higher intensities at the same measurement time as previous-generation models.

SCHEMATICS

VIDEO

Watch video demonstrations of the SPECTROCUBE

BROCHURES

SPECTROCUBE for Precious Metals (PDF, en)

Read MoreWHITEPAPERS

Analyzing Precious Metals (PDF, en)

Precious metals require — and reward — careful analysis. But analysts face various difficulties. The scope of precious metals analysis extends from trace levels to 100%. Most of these metals are resistant to dissolution by all but the strongest acids. Some traditional analytical methods like fire assay are time-consuming and demand a high level of skill.

Three modern techniques offer widely used solutions. Energy-dispersive X-ray fluorescence (ED-XRF) and optical emission spectrometry (OES) can be used without specialist analytical training to rapidly and accurately analyze bullion, jewelry, and alloys. A variation of OES, inductively coupled plasma optical emission spectrometry (ICP-OES), is an ideal tool for the analysis of bulk materials such as ores, and for the determination of trace impurities.

Several instruments available from SPECTRO Analytical Instruments represent the state of the art in these techniques. This paper describes their application to precious metals analysis.

APPLICATIONS

Application Reports

Application Brief: Precious Metals Testing with ED-XRF Spectrometry (XRF-115-AB)

SPECTROSCOUT – The portable, energy-dispersive X-ray fluorescence (ED-XRF) spectrometers that bring lab-grade analysis into the field or onto the production floor

OVERVIEW

- Light weight and portable elemental analyzer for precious metal alloys; spot size is only 1 mm

- Fast and on-site: Elemental analysis of rock, sediment and soil. Element range starting from Na, detection limits for relevant trace elements significantly lower compared to other portable and handheld XRF instruments.

- At the production line: High productivity with application specific packages. Small footprint with high analytical power.

The new portable SPECTROSCOUT ED-XRF analyzers deliver much of the analytical power of top-grade laboratory benchtop analyzers. They provide fast, dependable, truly lab-quality results in the field or on the production floor – all at a surprisingly low cost. The SPECTROSCOUT analyzers provide exceptional performance, at wide concentration levels, for all of the relevant elements in the range of Na-U. SPECTROSCOUT impresses with unprecedented precision and speed making it the ideal portable XRF for onsite applications where results matter.

Available in two versions for field & offsite testing or laboratory & at-line testing, these new, portable spectrometers provide exceptional performance. Visit the SPECTROSCOUT Resource Center for more details and application examples.

Simplified software is accessed via a touchscreen interface. Predefined application packages are designed to fit the task at hand. Unique iCAL calibration takes just one sample and only five minutes for standardization. And an optional integrated video system allows precise spot testing, plus image storage.

Its light weight and small size makes SPECTROSCOUT the ideal portable XRF spectrometer solution for at-line as well as field and offsite applications.

BROCHURES

SPECTROSCOUT – Precious Metals

Read MoreWHITEPAPERS

Analyzing Precious Metals (PDF, en)

Precious metals require — and reward — careful analysis. But analysts face various difficulties. The scope of precious metals analysis extends from trace levels to 100%. Most of these metals are resistant to dissolution by all but the strongest acids. Some traditional analytical methods like fire assay are time-consuming and demand a high level of skill.

Three modern techniques offer widely used solutions. Energy-dispersive X-ray fluorescence (ED-XRF) and optical emission spectrometry (OES) can be used without specialist analytical training to rapidly and accurately analyze bullion, jewelry, and alloys. A variation of OES, inductively coupled plasma optical emission spectrometry (ICP-OES), is an ideal tool for the analysis of bulk materials such as ores, and for the determination of trace impurities.

Several instruments available from SPECTRO Analytical Instruments represent the state of the art in these techniques. This paper describes their application to precious metals analysis.

APPLICATIONS

Application Reports

XRF-79: Analysis of Precious Metal Alloys (SPECTROSCOUT)

XRF-79: Analysis of Precious Metal Alloys Excitation of the fluorescence radiation in a sample by an X-ray tube has been optimized so that the required precision for the analysis of jewelry alloys can be achieved even with short measuring times, first results are typically displayed already after 7 to 10 seconds. The analysis screen supplies the operator with all necessary information at a single glance and can display the measurement result in different views - even during measurement. The analytical results are stored and can be displayed later, printed out and, after transfer to an external computer, processed with the “Result Manager” software.

Determination of Trace Elements in Gold

Inductively coupled plasma optical emission spectrometry (ICP-OES) is a powerful method for the determination of trace elements in Au or Au jewellery alloys. Using the simultaneous SPECTRO CIROS VISION spectrometer excellent detection limits, in the µg/kg-range, for trace elements in gold are achieved. Additionally, the Au content of a 99.9 % (m/m) gold can be obtained by subtraction of the total determined content of impurities in the sample from 100%.

Over the last 25 years ICP-OES spectrometers, also known as ICP-AES or ICP plasma spectrometers, have become an indispensable tool for chemical elemental analysis. Optical emission spectrometers with inductively coupled plasma (ICP plasma) excitation sources offer ease of use, high sensitivity and precision and relative freedom from interferences. ICP-OES systems have now become the analytical method of choice for a wide range of applications.

Since the introduction of its first ICP spectrometer, SPECTRO has managed to continuously set performance benchmarks.

Today, the new SPECTRO ARCOS*, an ICP instrument with a unique optical system, is probably the most powerful, flexible, and fastest ICP spectrometer, the world has ever seen.

Also learn more about the incomparable SPECTRO MS, the first ICP MS (ICP mass spectrometer) to be able to fully simultaneously determine not only the element contents, but also the isotope ratios in the entire mass range from Li to U.

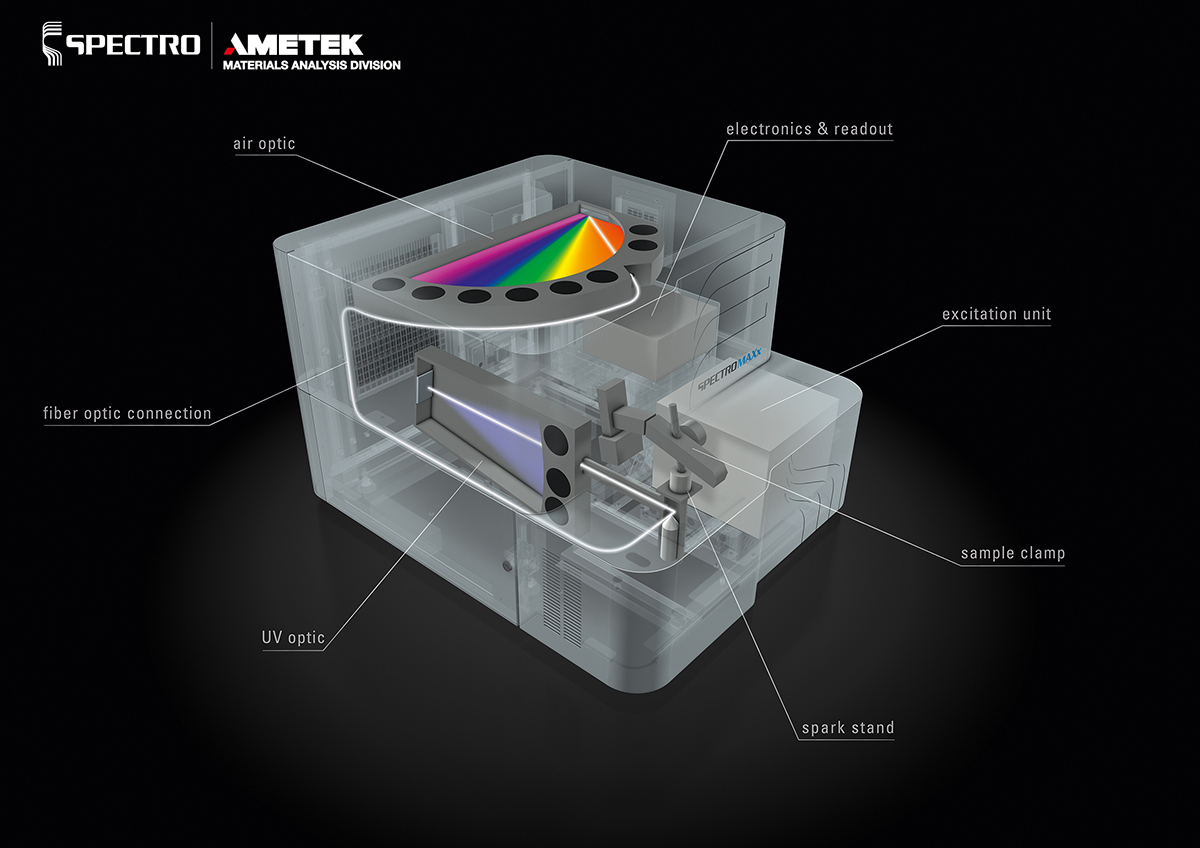

SPECTROMAXx with iCAL 2.0 – Worldwide the Metal Analyzer of Choice

OVERVIEW

- Even greater intelligence: Unique iCAL 2.0 one sample standardization helps maintain the same standardization – regardless of most temperature shifts and saves on average 30 minutes per day

- Even faster speed: Measurement times reduced by 12% over the previous model (example: low-alloy steel measurement time reduced by 3 seconds)

- Even better performance: Ideal for routine analysis and precise analysis of all incoming/outgoing materials and for process control (including nitrogen) in foundries – covering 10 matrices, 65 methods and 54 elements, at lower operating costs and minimal maintenance requirements

The SPECTROMAXx stationary metal analyzer is used mainly for material testing in foundries and for incoming and outgoing inspections in the metal industry around the world. It determines all of the elements used in the metal industry, including metal analysis of carbon, phosphorous, sulfur and nitrogen.

The eighth generation of the SPECTROMAXx arc spark OES metal analyzer comes with drastically reduced operating costs, significantly shorter measuring times and less maintenance requirements – while still offering exceptional precision and stability. And when it comes to productivity, the new SPECTROMAXx sets the benchmark.

It features truly intuitive operation, with the use of toolbar buttons, a user management system, and a clear separation of operation from programming of the instrument. The measurement is controlled with clear symbols and toolbar buttons. Once a workflow has been started, only the functions that are logical at any point in time along the way are active in the control software – all other commands are hidden. With the new application profiles, customer specific information can be set before beginning operation, relieving laboratory technicians of administrative activities.

The SPECTROMAXx arc/spark OES metal analyzer independently monitors all operating parameters. It dynamically determines the measurement time required based on the given sample properties and even shows when the spark stand needs to be cleaned depending on the type of samples being examined. The optional AMECARE machine-to-machine (M2M) support allows proactive alerts, backed up by direct connection with a remote SPECTRO service expert’s PC.

SCHEMATICS

WHITEPAPERS

SPECTRO Whitepaper Analyzing Precious Metals (PDF, en)

Read MoreSPECTROLAB – Ultimate performance for the next generation of metal analysis

OVERVIEW

- Ultimate elemental flexibility – covering 15 matrices, 68 methods, 65 elements and 210 lines (not counting reference lines); quick addition of elements and methods without hardware changes (SPECTROLAB CCD version)

- Simple standardization with only one sample – based on SPECTRO´s Intelligent Calibration Logic (iCAL) – saves on average 30 minutes per day (SPECTROLAB CCD version)

- Excellent ease of use for effortless operations – simplified operator view presents clear choices via dedicated toolbar buttons

The new generation of SPECTROLAB OES analyzers delivers the greatest innovation in elemental analysis yet. Stability, flexibility, and analytical functionality combine in a high performance package that is in a class of its own. Available in hybrid PMT/CCD and breakthrough new all-CCD versions, this analyzer sets a new standard for R&D and process/quality control.

Both the third-generation hybrid and brand-new all-CCD SPECTROLAB models offer excellent optical performance for metals industry applications. The hybrid version provides unbeatable precision, flexibility, and stability for specialized R&D laboratories. It’s especially suitable for testing new materials, and for precious metals trace elements and inclusions.

The all-CCD version delivers impressive reproducibility, stability, and speed, along with advantages such as fast, simple iCAL calibration. These make it ideal for time-critical applications such as process control and quality control inspection of incoming/outgoing materials.

The unit’s new Spark Analyzer Pro software presents a revolutionary new level of operator interface simplicity. The program includes straightforward, self-explanatory icons and a familiar, ergonomic approach with little learning curve. Only authorized users can access the method development / knowledge base module for more complex tasks.

SPECTRO has spent more than 30 years developing the world’s leading OES instruments. A host of improvements, enhancements, and groundbreaking technological innovations make its new spectrometer the ideal analytical answer for primary metal producers and other critical applications.

BROCHURES

WHITEPAPERS

SPECTRO Whitepaper Analyzing Precious Metals (PDF, en)

Read More